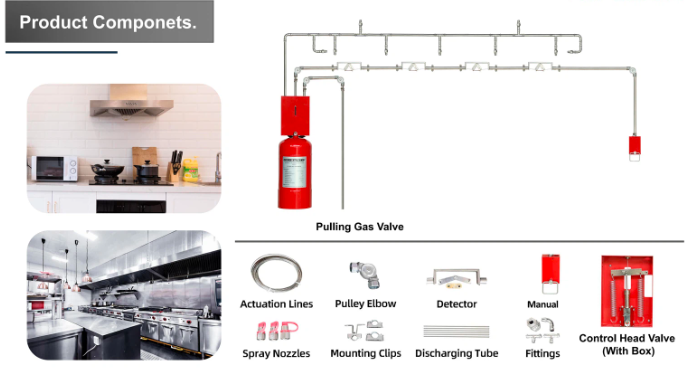

Restaurant Class K Kitchen Hood Automatic Fire Suppression Systems

IJFFG kitchen fire suppression systems have been specifically designed to protect home/commercial kitchen and put out cooking fires caused by grease Orgreave-laden vapors (class F or class K fire) quickly and efficiently.

These self contained pneumatic systems require no external energy or power supply. Upon flame impingement or heat, the pressurised detection tubing will burst and activate the cylinder valve to open and release the extinguishing agent.

IJFFG kitchen fire suppression systems are specifically designed to extinguish fires fueled by grease and in a kitchen environment. They use wet chemicals in a fine mist to quickly extinguish fires and offer a quicker clean-up than dry chemicals.

Product Advantages

* Simple, high quality and well engineered system. Easy to install

* Fast, automatic actuation

* Stainless steel pipework, fittings and nozzles to suit kitchen environments.

* Linear heat and flame detection, allowing for multiple of detection points. Flexible piping requirements

* Remaining operational during power interruption

* Quick, easy clean up once appliances have cooled, the agent can be easily wiped away from equipment

Product Specification

| Agent Capacity (L) | 6L X 1 | 10L X 1 | 15L X 1 | 20L X 1 | 25L X 1 |

| Spray Nozzle (pc) | 5 | 8 | 12 | 16 | 20 |

| Temp. Detector (pc) | 2 | 4 | 6 | 8 | 8 |

| Fuel cut-off valve | Depending | ||||

| Protective Range | 2~3m | 3~5m | 5~8m | 8~10m | 10~12m |

| Pulley | 6 | 6 | 8 | 10 | 10 |

| Activation Temperature | 185℃ | ||||

| Discharging time (S) | ≥30S | ||||

| Working Temp (℃) | 0-55℃ | ||||

| Working Pressure(Bar) | 14Bar | ||||

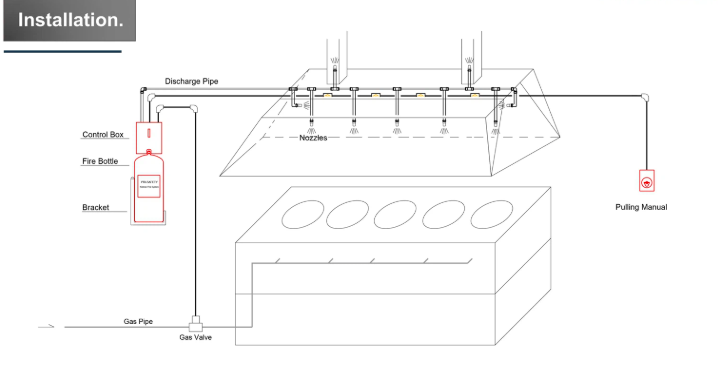

Working Diagram

How it works?

Step 1 --- When there is a fire, the detection tube ruptures to a hole when the temperature reach to 140ºC .

Step 2 --- The resulting drop in pressure causes the head valve to be activated.

Step 3 --- The head valve open, and the agent discharge through the tube to the spray nozzles.

Step 4 --- Agent cover the fire area and extinguish the fire quickly and thoroughly.

This system is totally automatic and independent of electricity.

Product Application

Packing & Delivery